AT THE PULS OF TIME.

Please also visit our Linked In page, with the latest developments:

JEC 2024 - Material & Simulation Driven Design as a driving force for aviation, new space and automotive innovations

The new developments in aviation require a clear increase in the production volume of composite components. The sector can benefit from the experience of other industries, such as the automotive industry, in order to produce components in a more automated and cost-effective way.

Similarly, the automotive industry has been undergoing a significant shift towards electrification for years. The growing demands on future battery storage systems and the entire e-drive train are at the heart of this change. As a result, the use of high-pressure RTM (HP RTM) with glass fiber-reinforced plastics in the growth market of China, for example, has proven to be extremely competitive compared to other technologies and materials.

However, new material systems such as wood and wood-based products are also entering the market and are being rapidly enabled for new applications. Here, recyclability plays a decisive role for future value chains.

New markets, technologies and applications are paving the way for future innovations in large-scale production with composite materials. Material & Simulation Driven Design from FE supports your company in developing the right products for your success.

Let’s find out together what opportunities are available for your company and visit us in Hall 5/K110.

CAN WOOD MAKE THE AUTOMOTIVE INDUSTRY GREENER?

Join us at the IAA 2023 where Forward Engineering dives into this exciting question. With the industry’s shift towards sustainability and reduced carbon footprint, challenges appear for all stakeholders. Could a renewable, carbon-sequestrating material meet the complex needs and requirements of the automotive sector?

Prepare to be amazed by wood’s potentials and possibilities – shown in a door impact beam, together with our partner Weitzer Wood Solutions. Our collaboration sets the focus on the entire value chain: from conceptual multi-material-design and simulation to automated mass production and end-of-life recycling with wood as a material!

Let’s discuss your future opportunities together! Visit us in hall B1 booth E30.1 to learn more.

FORWARD ENGINEERING PRESENTS FUTURE DEVELOPMENTS AND TRENDS IN THE FIELD OF „DESIGN FOR SUSTAINABILITY”, FUTURE BODY & BATTERY DESIGN AT JEC WORLD 2023 - SPECIAL: BOX THERMAL RUNAWAY TESTING ACCORDING TO UL2596

Meet our team and learn more about the latest developments and trends in sustainable product development with engineering plastics and how extensively real sustainability needs to be considered in the early phase of product development.

Another topic is the holistic battery development, its integration into the vehicle structure and the ever-increasing demands on the overall system. Forward Engineering will present a testing program developed in partnership with UL (Underwriters Laboratories) and Hyundai North America and how these materials tests help to improve battery safety and performance in line with the UL2596 test standard.

This standardized “box thermal runaway test” provides reliable predictions of material behavior under the influence of temperature, pressure and particle flow and is increasingly required by automobile manufacturers worldwide.

We are looking forward to your visit in Paris.

K-Show では、サーキュラーエコノミーについて我々は何を学ぶことができるのでしょうか。

10月19日から26日までドイツのデュッセルドルフで開催されるK-Showでは、業界のリーダーたちが一堂に会して見識を共有し、最新のプラスチックテクノロジーを紹介します。

今年のK-Showは、循環型経済と持続可能なプラスチック産業への道筋がどこまで進んでいるかを示す重要な指標となるでしょう。 原材料から最終製品、そしてそれらを製造するための高度な技術に至るまで、参加者は業界がグローバルな規制や市場の圧力にどのように対応しているかを直接目にすることができます。

フォワードエンジニアリングは、三井物産株式会社のブースで共同出展し、持続可能なソリューションの開発と検証を通じて、お客様のビジネスの持続的成長をいかにサポートするか、その見識を共有できることを嬉しく思っています。 簡単なライフサイクルアセスメントから包括的なサステナビリティ・ロードマップ開発プログラムまで、当社のチームはお客様の成長目標の実現を支援するユニークな立場にあります。

ホール7 ブース7AD32にてお待ちしておりますので、是非お立ち寄りください。

FRTP Battery Enclosures, Sustainability and LCA/PEF Analysis to be featured at Forward Engineering’s collaborative presentations during this year’s JEC WORLD EXPO 2022

JEC World 2022 is only a few days away! The Forward Engineering team is happy to support the event with personal contributions. Plan to meet up with our colleagues to learn more about the latest developments in BEV structures and sustainability. Georg Käsmeier and Dana Miloaga/ Johns Manville will jointly present the use of new organosheets in future battery housings. At our booth we provide information on the latest trends and experiences in the field of “Design for Sustainability” and the correct use of Life Cycle Analysis (LCA/PEF) in product development or for balancing composite materials. CU there!

FORWARD ENGINEERING JAPAN HAS MOVED TO THE “NAGOYA MITSUI NORTH BUILDING”

After two intense years and unimaginable circumstances, Forward Engineering Japan (FEJ) is excited to announce that we have moved to a new location. With the extensive resources available in Japan’s automotive industry center, Nagoya remains an excellent place for us to call home. Our new offices include enhanced multi-media conferencing which simplifies our ability to host multiple client meetings and workshops concurrently. The convenient location, adjacent to the Nagoya train station, will make it even easier for people to visit as we look forward to a post-covid return to in person meetings. We look forward to hosting you for a visit to our new location when conditions permit. In the meantime, please take note of our new address as outlined below and update our contact information in your files:

NAGOYA MITSUI NORTH BUILDING (8-18, Meieki 4-chome, Nakamura-ku, Nagoya-shi, Aichi

450-0002, Japan)

FORWARD ENGINEERING IN CLOSE COLLABORATION WITH PARTNERS DEVELOPS A NEW COST-EFFECTIVE MODULAR CELL-TO-PACK HIGH VOLTAGE GFRP SMC BATTERY ENCLOSURE

Through close collaboration with industry leading partners, Evonik Industries AG, Lorenz

Kunststofftechnik GmbH and LION Smart GmbH, Forward Engineering GmbH has developed an exciting

new composite intensive high voltage battery enclosure.

This fresh new modular mixed material approach enables a cost-effective scalable solution for a range

of vehicle applications. Featured within the design is a new high performance GFRP SMC compound

which delivers the unique combination of exceptional mechanical performance, extreme fire resistance

together with ease of manufacturing processability. Please see the attached release, or contact us

directly, to learn more about this exciting program.

COLLABORATION BETWEEN FORWARD ENGINEERING AND LEHMANN & VOSS

Design, Materials and Processing. DfAM (Design for Additive Manufacturing) encompasses all of these

elements. Forward Engineering North America´s collaboration with LEHVOSS Group of North America

and the establishment of our Additive Manufacturing Labs in Detroit and Munich is helping to

accelerate the development of functional structural 3D printed parts for the Automotive/Mobility

industry. Together we are helping OEMs and Tiers leveraging the power of Additive Manufacturing

DEVELOPMENT PROCESS FOR AN ELECTRIC VEHICLE MIXED MATERIAL BATTERY ENCLOSURE

17 rd July 2020, 9:00 – 10:00, Webinar of Composites United e.V.

Speaker: Denis Schmitz, Forward Engineering GmbH

Forward Engineering presents challenges and concepts for the development of mixed material battery

enclosures. The presentation material is in English, spoken in german.

"(IT'S NOT EASY) BEING GREEN" - A HOLISTIC APPROACH FOR A SUSTAIN PRODUCT DEVELOPMENT PROCESS

3 rd June 2020, 9:00 – 10:00, Webinar of Composites United e.V.

Speaker: Markus Beer, Forward Engineering GmbH

Forward Engineering will show the development framework “Design for Sustainability” with examples of

applications how to adopt the methodology to your product portfolio.

FORWARD ENGINEERING PRESENTS AT THIS YEAR´S “STRUCTURAL THERMOPLASTIC COMPOSITES CONFERENCE -(TCC2020)”

The first Virtual Thermoplastic Composites Conference (TCC2020), presented by ACMA and

Composites Manufacturing was a great and interesting online experience.

Our presentation on Accelerating the Deployment of Structural Thermoplastic Composites for Next

Generation Automotive and Transportation Applications was received very well with excellent questions

from the engaged audience of participants.

Strong interest in collaboration around Material Card generation and sharing was a key take-away from

the event. Forward Engineering’s Material Card Development Program was designed exactly for this

reason and we are excited to play such an important role in the growth of structural thermoplastic

composites.

Meeting with exhibitors and attendees through the online platform and the live feedback through the

chat function during the presentations was a unique way to measure audience engagement real time.

Thank you to the ACMA and everyone that participated in this very special event. We look forward to

continuing the very interesting discussions around accelerating the growth of Structural Thermoplastic

Composites and welcome those we have yet to connect with to contact us directly to join the

conversation!

SUCCESSFULL DEVELOPMENT OF COMPOSITE DOMINATED MULTI-MATERIAL CAR PLATFORM FOR CHANGAN

The Chinese vehicle manufacturer CHANGAN has successfully produced the 1st government funded

composite dominated multi-material car platform in its Chongqing factory on March 20th 2020.

Our subsidiary, KDX Design Center was responsible for engineering development of the body in white

& closures from pre-study phase to final data release incl. strong support for all material, process

and assembly related topics.

The body structure consists of 2 modules – with the upper made mainly from CFRP incl. high

strength steel and lower frame made entirely from aluminum.

The major challenge of this fast lane development project is to achieve a robust design within short

development period and at the same time to meet high weight-performance targets (over 30%

lightweight to metal, 5 stars CNCAP rating). In addition, over 10 different local materials and 4

manufacturing technologies need to be qualified and used for body structure, which requires full

understanding of different material behaviors and specific material development strategy [MODULAR APPROACH ©FE].

The vehicle structure has been validated by FEA simulations and several tests including full vehicle crash tests.

After the entire vehicle validation tests and further optimizations, the multi-material structure

concepts are expected to be transformed into mass production applications at CHANGAN Group.

NEW SMC MATERIAL ENABLES ECONOMIC LIGHTWEIGHT CONSTRUCTION OF BATTERY ENCLOSURES

In cooperation with its joint venture Vestaro, Forward Engineering has developed a multi-material design

for a battery enclosure. The central component is the cover structure, which is based on the Sheet

Molding Compound (SMC) technology. By using a specially developed hardener for epoxy SMC systems

from Evonik, a cost-efficient and mechanically highly resilient lightweight design could be realized. In

cooperation with the manufacturing partner Lorenz Kunststofftechnik and the battery system developer

LION Smart, this development was presented and validated within a holistic battery system concept. The

preliminary project results were published in the JEC Magazine (issue 133).

FORWARD ENGINEERING EXPANDS GLOBAL TEAM WITH THE ESTABLISHMENT OF FORWARD ENGINEERING NORTH AMERICA

We are proud to announce the establishment of Forward Engineering North America, LLC (FENA)

and the appointment of Adam Halsband as Managing Director of our North American Operations.

The Forward Engineering team has been supporting North American clients and collaborating with

regional technology partners on the accelerated adoption of composite intensive mixed material

solutions since several years. Electrification, automation and demand for cost effective innovation

has fueled a steadily increasing demand for FE’s unique production-based design and engineering

services in the North American market.

With our new office in Metro Detroit and a dedicated team on site we are now even closer to our

customers and partners to support the growth of Forward engineering globally and especially in

the North American market.

Read the official press release here:

FORWARD ENGINEERING PARTICIPATES AT THE JEC WORLD EXPO PARIS FROM MARCH 3RD TO 5TH AND SHOWCASES BATTERY ENCLOSURE DEVELOPMENT

Achieving the optimal balance of Mass/Cost/Performance is critical to the adoption of advanced

materials and manufacturing processes in the very competitive automotive industry. Forward

Engineering team members will be presenting the fundamentals of battery enclosure to vehicle

structure integration as well as case studies demonstrating the potential for cost effective

lightweighting with composite intensive mixed material solutions.

“Electrification presents a unique challenge for the transportation industry and the opportunity for

Forward Engineering to support our OEM and Supplier partners with development and validation of

some of the most exciting new composite intensive mixed material designs.” Stated Robert Maier

– Managing Director. “We are looking forward to share those stories with visitors to the JEC World

in Paris this year.”.

Please stop by our exhibit at Composites in Action Hall 6 Stand D85 to learn more.

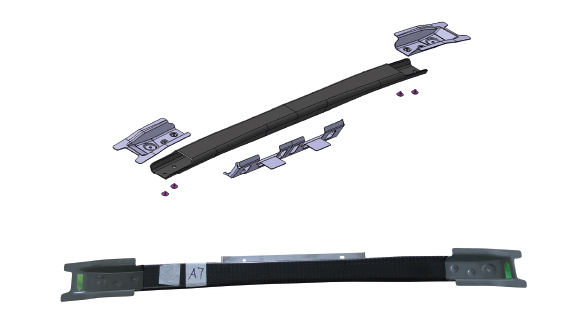

WOVEN ROOF BOW WINS 1ST PLACE AT THE CHINA LIGHTWEIGHT DESIGN AWARD

Our joint venture, KDX Design Center, has developed a braided composite roof bow for the Chinese vehicle manufacturer BAIC. KDX DC was responsible

for concept development, material and technology selection, material characterization and supplier management.

The jury was impressed by the load-path design with cost-efficient material selection (CF and GF), the coreless braiding structure, hybrid joining

and the variable cross-sections for flexible interfaces, as well as by the technical performance data (weight: -36.5%, compressive strength: +10%,

flexural strength: +60%, torsional stiffness: 10-fold, costs: -50% compared to the industry average) of the fiber composite roof bow.

In the end, 5000 professionals and 7 industry experts awarded the project with the

1st place.

More information at:

HTTP://WWW.SOHU.COM/A/336617136_620780

KDX DESIGN CENTER NOMINATED FOR NIO LIGHTWEIGHT CARBON FLOOR AT JEC INNOVATION AWARD 2019

Anew we can proudly announce that our Chinese production partner Kangde Composites Co, Ltd (Langfang, China) KDC together with our joint venture KDX Roding Europe Automobile Design Center GmbH (Munich, Germany) and two other partners are once again among the finalists for the JEC Award 2019 in the category “Automotive Application”.

This year we are nominated for the innovative NIO Composite Floor of the NIO ES6, which was created through the close cooperation of a global network of experts. Despite its low weight (>30% weight saving compared to Al baseline) it offers outstanding vehicle performance (torsional stiffness 44,930 Nm) with 5-star NCAP safety. Furthermore, it can be produced cost-efficiently in high volumes due to a low cycle time (2.5 min) and a fully automated process.

Whether we can take the price for our NIO Composite floor home with us, we will find out on March 13 at this year’s JEC World in Paris. We are excited!

More information at:

WWW.JEC-WORLD.EVENTS/PROGRAM/INNOVATION-AWARDS/